European White Oak Flooring

Specializing in Clean and Natural Grade Oak Flooring: Choose VIFLOOR for Tailored OEM Solutions.

Engineered Oak Flooring Made in Cambodia

Inventory Stock in Savannah

VIFLOOR EXHIBITING AT SURFACE EVENT VISIT US ON Booth 212

Mandalay Bay • Las Vegas

Jan 24-26 2024

Excellence in Engineered Wood Flooring for 20 Years – Your ldeal B2B Partner

Meet Us at the Las Vegas Surfaces Flooring Exhibition.

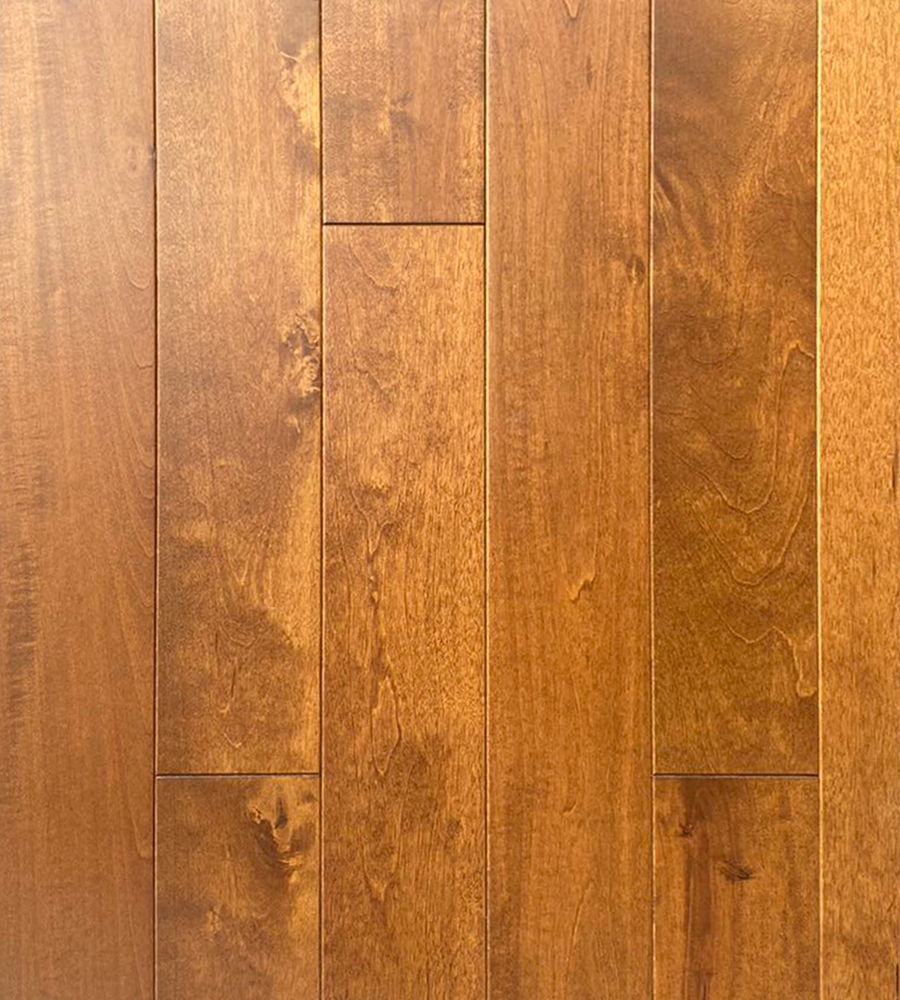

The Perfect Fusion of High Quality and Affordability

Specializing in Clean and Natural Grade Oak Flooring: Choose VIFLOOR for Tailored OEM Solutions.

Save Up to 30% on Your Oak Flooring Sourcing Costs

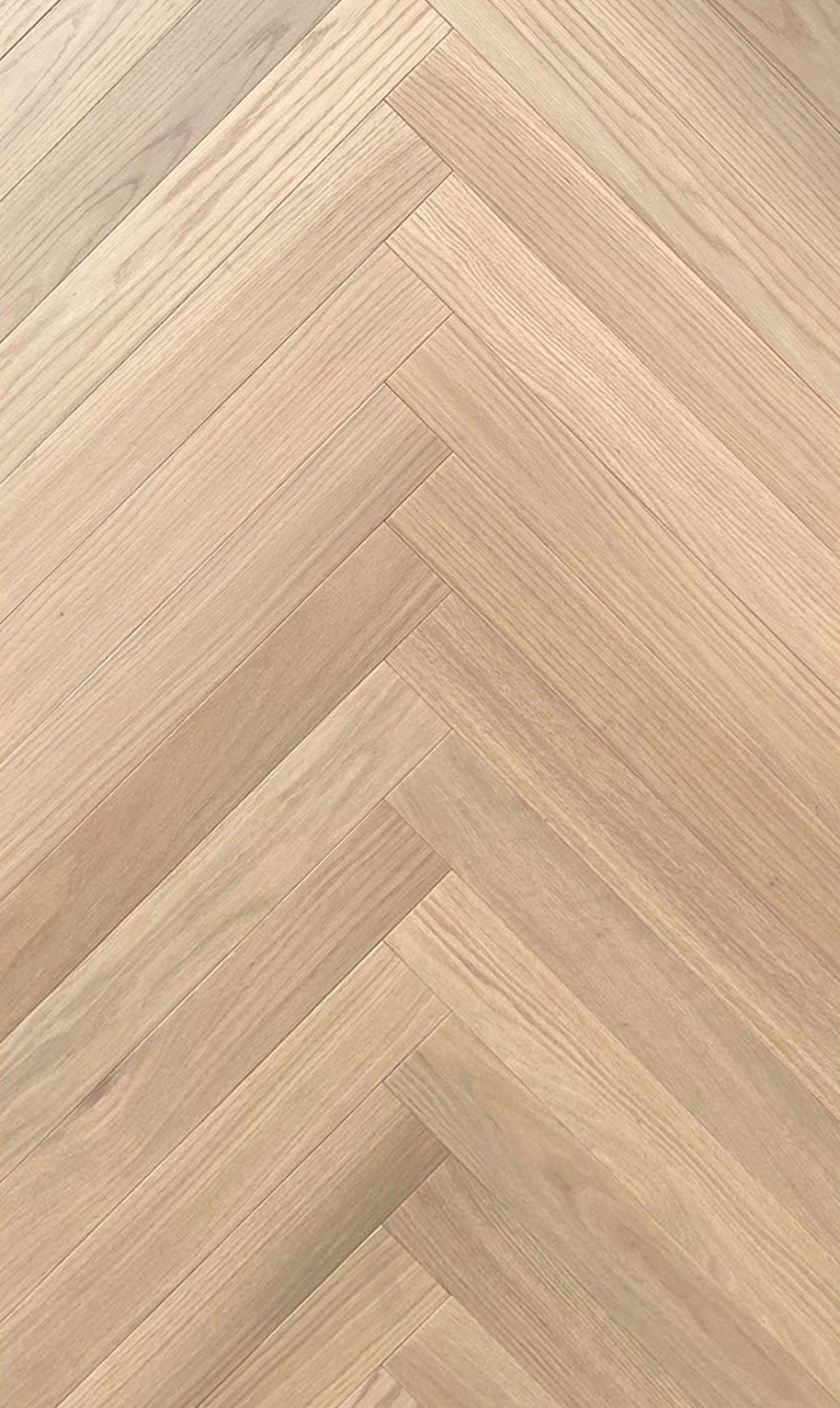

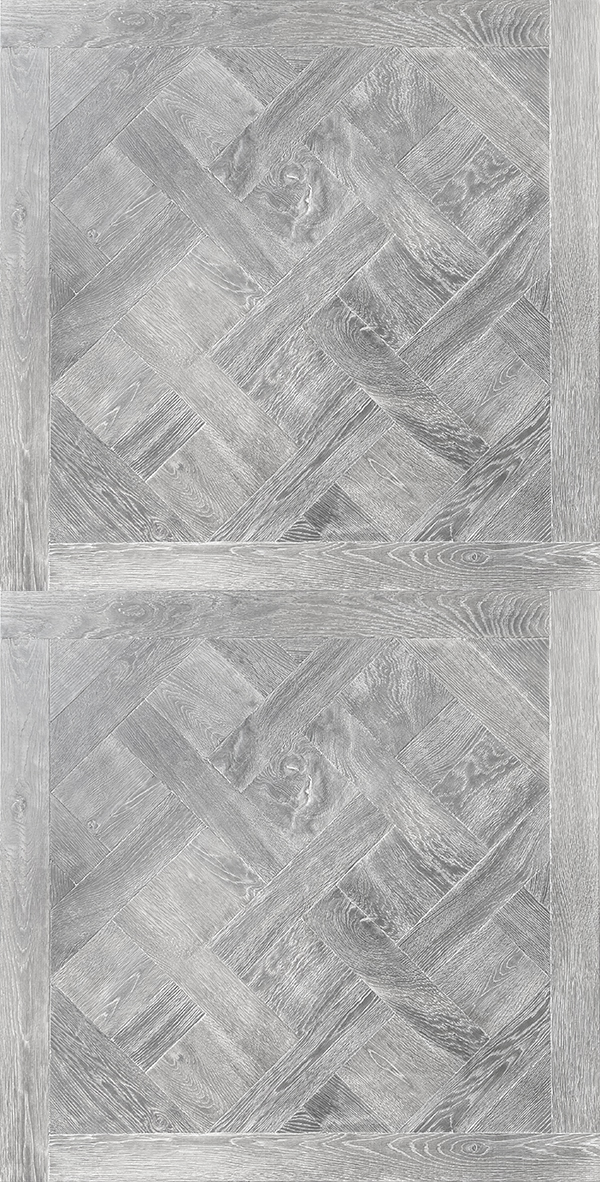

Designer’s Best Choice

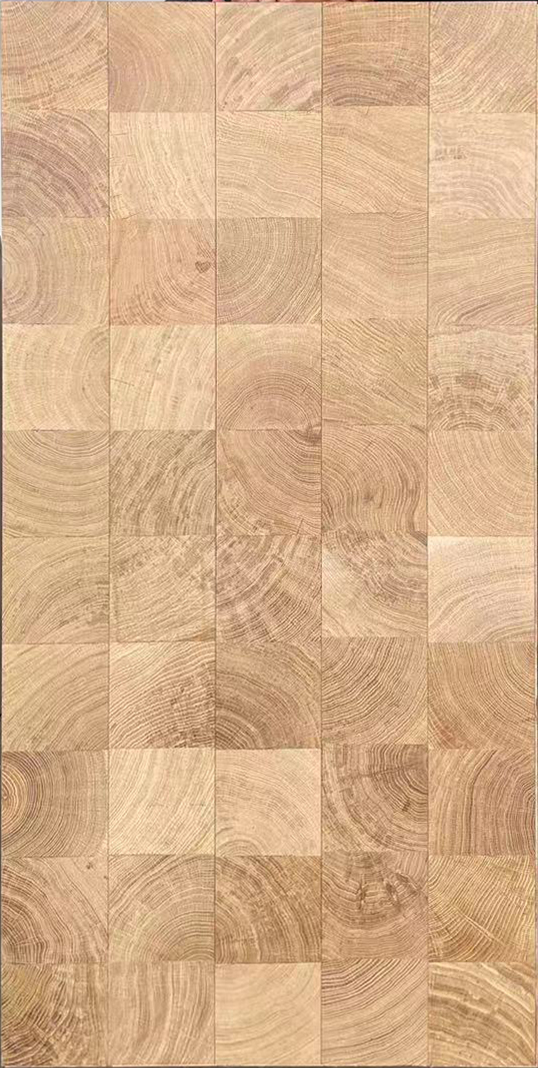

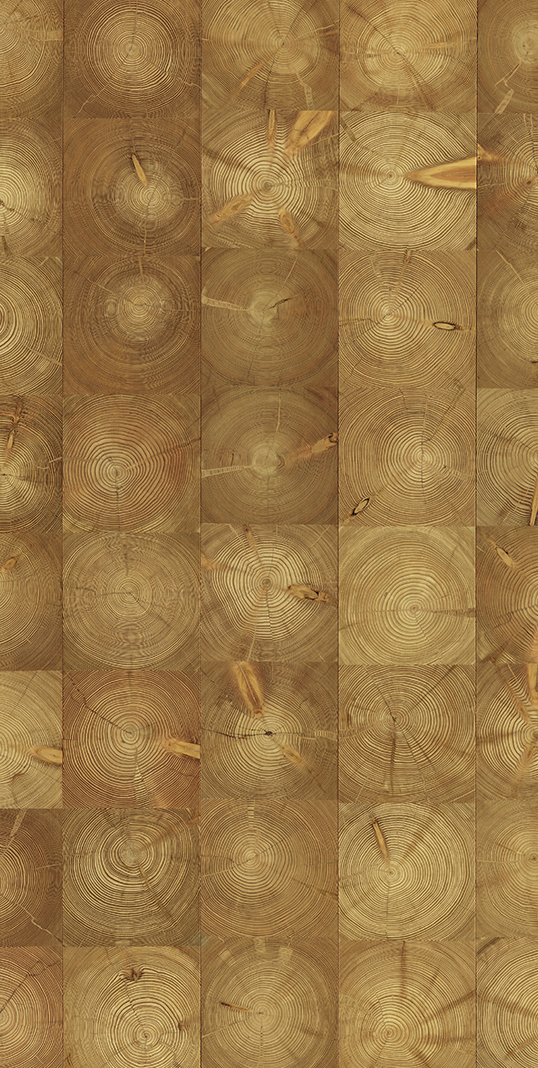

SHDRE01

The most Stable engineered End Grain, professional’s best Choice.

Elevate your inventory with our high-grade, competitively priced European oak flooring, the perfect fusion of luxury and cost-effectiveness.

Stability in Every Plank: Consistent Production, Quality, and Delivery. As a seasoned supplier to Europe’s largest wholesalers and America’s top retailers, our reputation is your guarantee.

VIFLOOR at Global Flooring Expos: A Legacy of Excellence

Discover the milestones of VIFLOOR’s journey through a curated gallery from prestigious flooring expos around the world. Witness our history of connecting with partners and showcasing top-tier engineered oak flooring solutions.

Our engineered oak flooring stands as a testament to our steadfast commitment to quality. With VIFLOOR, expect a partnership built on the bedrock of reliable quality, stable prices, and punctual delivery.

“From PEFC to CE and EUTR certifications, our credentials speak volumes. Dive into our FAQs, client testimonials, comprehensive services, and the story of VIFLOOR.”

If your wood floor features a click system joint between planks and is installed as a floating floor without bonding it to the subfloor, it can be lifted and re-laid multiple times. Even traditional T&G glue-down engineered wood flooring can be sanded and refinished to extend its lifespan and alter its appearance as desired. This unique characteristic of wooden floors allows them to be refreshed and rejuvenated without the need for replacement when redecorating.

To receive a sample of any of our products, simply click on the "CONTACT NOW!" button.

Solid wood floors are milled from a single piece of wood and have a consistent appearance throughout. In contrast, an engineered wood floor consists of a top layer of hardwood with cross-laminated layers of timber beneath, offering improved structural stability. This construction method minimizes movement and enhances stability, making it more resilient to fluctuations in temperature and humidity levels.

Solid wood floors are milled from a single piece of wood and have a consistent appearance throughout. In contrast, an engineered wood floor consists of a top layer of hardwood with cross-laminated layers of timber beneath, offering improved structural stability. This construction method minimizes movement and enhances stability, making it more resilient to fluctuations in temperature and humidity levels.

If the flooring is 14mm thick, a 20ft container can accommodate up to 1500M2 while a 40ft container can hold up to 2800M2. For 15mm thick flooring, a 20ft container can store up to 1300m2, and a 40ft container can hold up to 2600M2.

The answer largely depends on the preferences of the target market. The European market tends to favor 3-layer flooring, while the American market mostly prefers multi-layer flooring. However, the performance of the wood flooring remains the same regardless of whether it is 3-layer or multi-layer, with no significant functional differences between the two. Additionally, there is no major variance in the environmental requirements for both types of flooring. In terms of pricing, for the same specifications, 3-layer flooring is generally less expensive, lighter in weight, and requires less glue. The installation process for both types of flooring is similar, but currently, customers tend to favor locking products for three-layer flooring, as they can si

Regardless of whether it's a 4-sided or 6-sided carton, Songlinfloor guarantees the safety of the packaging and ensures that there is no functional difference between the two methods. The outer packaging is protected by a plastic sealing film. The only distinction between them is that 4-side cartons contain more boxes, which lowers packaging costs and reduces the consumption of cartons, while 6-side cartons offer a more high-end appearance. As a manufacturer, we highly recommend using 4-side cartons.

The delivery time for engineered flooring depends on the quantity of the order. On average, the production time ranges from 45 to 60 days.

Engineered Oak Flooring Made in Cambodia

Inventory Stock in Savannah

Excellence in Engineered Wood Flooring for 20 Years – Your ldeal B2B Partner

Meet Us at the Las Vegas Surfaces Flooring Exhibition.

We look forward to meeting you in the United States and building a successful partnership!

Discover the ideal flooring solution for your project with VIFLOOR! Reach out now for a free quote and expert advice on our custom multi-width engineered oak flooring. Email us at info@vifloor2006.com.